The invention of silicon chips revolutionised communications. Even right this moment they’re the cornerstone of the applied sciences we use to maneuver info around the globe.

The means they work has modified considerably, nevertheless. They have develop into higher: for a very long time this was as a result of consultants improved its {hardware} to function as effectively as attainable. But extra not too long ago, researchers have began to interchange the electrons with photons, the particles of sunshine, because the brokers answerable for storing and manipulating info.

Thus right this moment we’ve silicon photonics with useful purposes in information centres and sensors in addition to potential ones in quantum computing. Silicon photonics is shortly gaining traction because of the many benefits it gives over conventional semiconductor chips.

In a research in Nature, scientists from the US and Europe reported that they’d efficiently fabricated the primary miniaturised lasers immediately on silicon wafers, marking a big advance in silicon photonics.

Photons carry info sooner, with better information capability, and decrease power losses than electrons.

But photons aren’t silver bullets. A big problem related to utilizing photons is integrating the supply of those particles — a lightweight supply — with the silicon chip itself.

Currently, engineers’ greatest wager is to connect a separate laser mild supply to the chip. The ensuing machine operates extra slowly than a chip with an built-in mild supply due to the small however vital mismatches that come up because of being manufactured independently. Separately manufacturing and attaching the lasers can be costlier.

In the brand new research, the researchers surmounted this downside by ‘growing’ the laser immediately on a silicon chip, in a course of that can be extra scalable.

The analysis group additionally carried out its whole course of in an ordinary complementary metal-oxide-semiconductor (CMOS) manufacturing line, which the expertise business at the moment makes use of to fabricate digital chips. Thus the brand new approach could be suitable with current manufacturing strategies.

Getting on the chip

A typical silicon chip has 4 parts: a supply to supply the electrons or photons, waveguides, modulators, and photodetectors.

In a photonic chip, a laser is the sunshine supply. This is the toughest half to make on the silicon chip itself. The waveguides act as paths for the photons, much like how wires are paths for electrons.

Modulators are units that encode info onto mild (or decode info from a lightweight sign). They do that by transcribing the data in some bodily property of the sunshine, like various its depth, wavelength or section. (Similarly, they extract info by ‘reading’ these variations in an incoming service sign.)

Finally, photodetectors convert mild into electrical indicators.

Switching the laser on

In its easiest kind, a laser — an acronym of ‘light amplification by stimulated emission of radiation’ — works by amplifying mild in a course of known as stimulated emission.

Here, an electron in a better power stage is ‘kicked’ by an incoming photon to lose some power and drop to a decrease power stage. This power misplaced is within the type of one other photon whose power matches that of the incident photon. When this course of happens repeatedly, the inhabitants of electrons generates a coherent beam of sunshine. This is a laser.

Silicon itself can’t emit mild effectively because it has an oblique bandgap. In different phrases, in a silicon atom, an electron in a better power stage can not drop to a decrease one on its personal; as a substitute it requires an extra particle to assist launch the electron’s power and drop down.

Most lasers use semiconductor supplies like gallium arsenide to supply the sunshine. These supplies have a direct band hole, which means that electrons inside the fabric can drop from a better power stage to a decrease one by emitting a photon.

Direct band-gap supplies permit electrons to immediately emit photons with out requiring to be kicked, changing extra electrical power into mild with out extra interactions. Thus the laser is extra energy-efficient.

Integrating gallium arsenide with silicon is a significant problem due to the totally different association of atoms in every of the weather. When gallium arsenide is grown layer by layer on silicon, the mismatch within the crystal construction of the supplies causes imperfections the place the atomic patterns don’t line up correctly.

Imagine attempting to suit two puzzle items collectively when they aren’t a part of the identical puzzle.

When electrons encounter these defects, they lose power as warmth fairly than as mild, rendering the laser much less environment friendly.

In the trenches

In their research, the researchers efficiently created a chip that consisted of a silicon wafer base, nanometre-sized ridges via which photons travelled, and a small area that produced these photons.

The thought of the ridges got here from a 2007 research, wherein researchers from AmberWave Systems Corp. discovered that if gallium arsenide is deposited on silicon on the backside of a slender, deep trench surrounded by an insulating materials, the defects develop into ‘trapped’, which means they don’t intrude with the laser’s final operation.

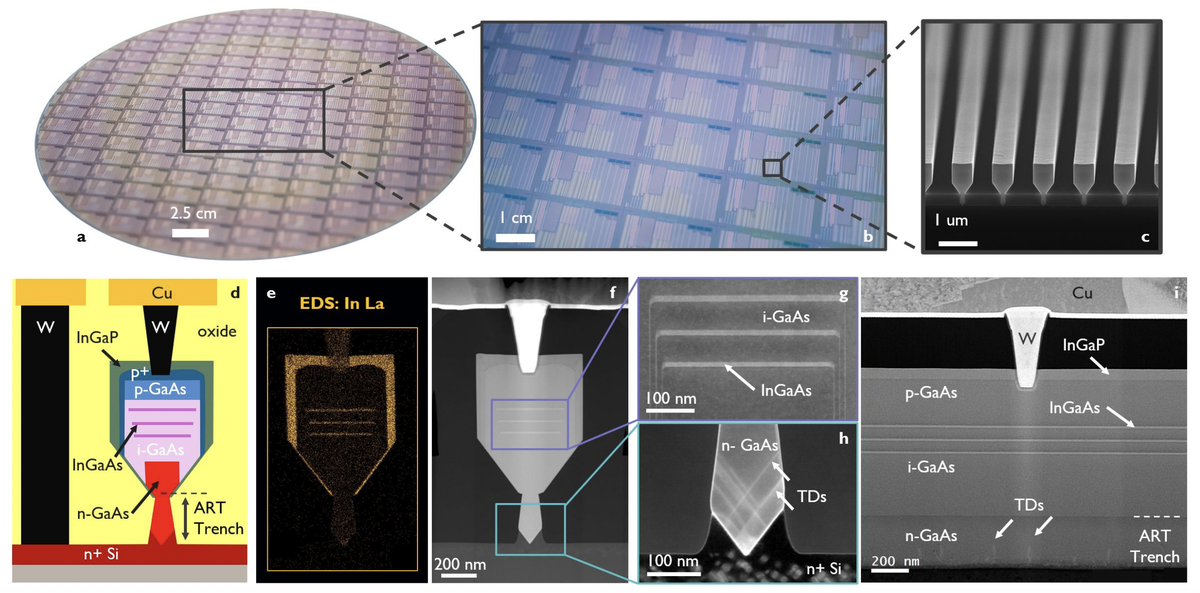

Top, L-R: {photograph} of a fabricated 300-mm silicon wafer containing 1000’s of GaAs units; close-up view of a fabricated 300 mm wafer displaying a number of dies; and scanning electron micrograph of a GaAs nano-ridge array earlier than encapsulation. The backside row reveals numerous parts of chip.

| Photo Credit:

arXiv:2309.04473v1

So the researchers carved nanometre-wide ridges in a 300-mm lengthy silicon wafer, and utilized silicon dioxide because the insulating materials. Any defects have been confined to the underside of those trenches, permitting a defect-free gallium arsenide crystal to develop above.

Next, on the identical wafer, the researchers deposited three few-atoms-thick layers of indium gallium arsenide (i.e. gallium arsenide the place 20% of gallium atoms had been changed with indium to realize optimum mild emission). These layers collectively functioned because the laser.

Finally the group deposited a layer of indium gallium phosphide on high of the entire setup for cover.

To make the laser work, the researchers added electrical contacts linked to an exterior present supply. When a present flowed into the indium gallium arsenide area, the latter emitted photons that flowed via the waveguides.

Solving a long-standing downside

The researchers have been capable of embed 300 purposeful lasers on a single 300-mm silicon wafer.

The dimension of the wafer is necessary as a result of it’s the business normal in fashionable semiconductor manufacturing, and may thus be built-in with out demanding vital adjustments.

The laser produced mild with a wavelength of 1,020 nm, which is well-suited for the short-ranged transmissions between pc chips.

Thus the researchers count on their chip could result in a considerable enchancment in computing efficiency and cut back power consumption in information centres.

The threshold present required to run the laser was as little as 5 mA, similar to that required for an LED in a pc mouse. The laser’s output was round 1 mW.

The laser could constantly function for 500 hours at room temperature (25° C). At round 55°C, its effectivity dropped.

While this length is promising, current analysis on optical silicon chips has demonstrated steady operation at temperatures as much as 120°C, highlighting ongoing challenges in growing steady semiconductor lasers.

In sum, the photonic silicon chip is novel as a result of it’s the primary demonstration of a totally monolithic laser diode on a silicon wafer of this dimension. The group’s course of can be scalable and cost-effective.

Tejasri Gururaj is a contract science author and journalist with a grasp’s diploma in physics.

Published – April 15, 2025 05:30 am IST